close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

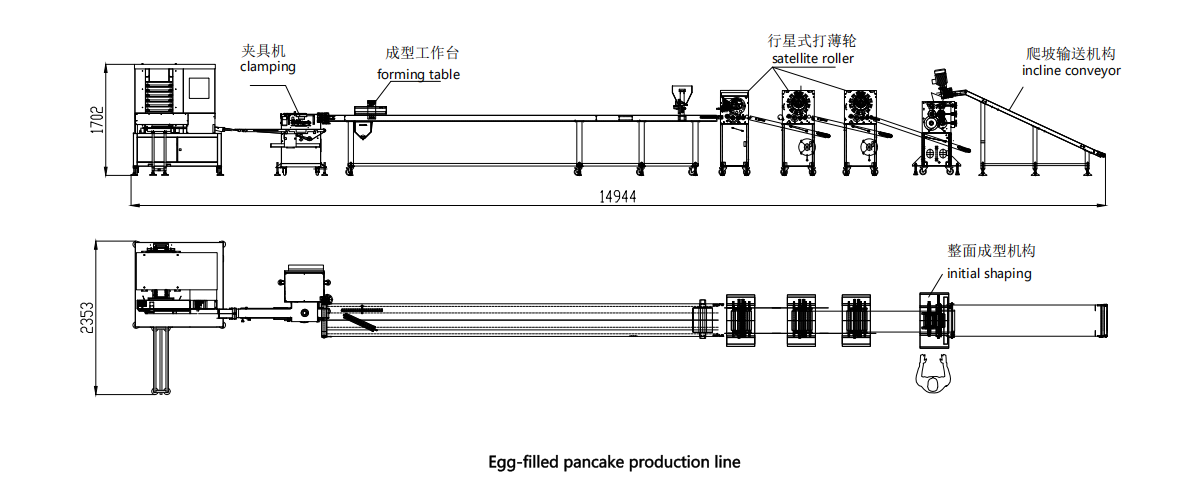

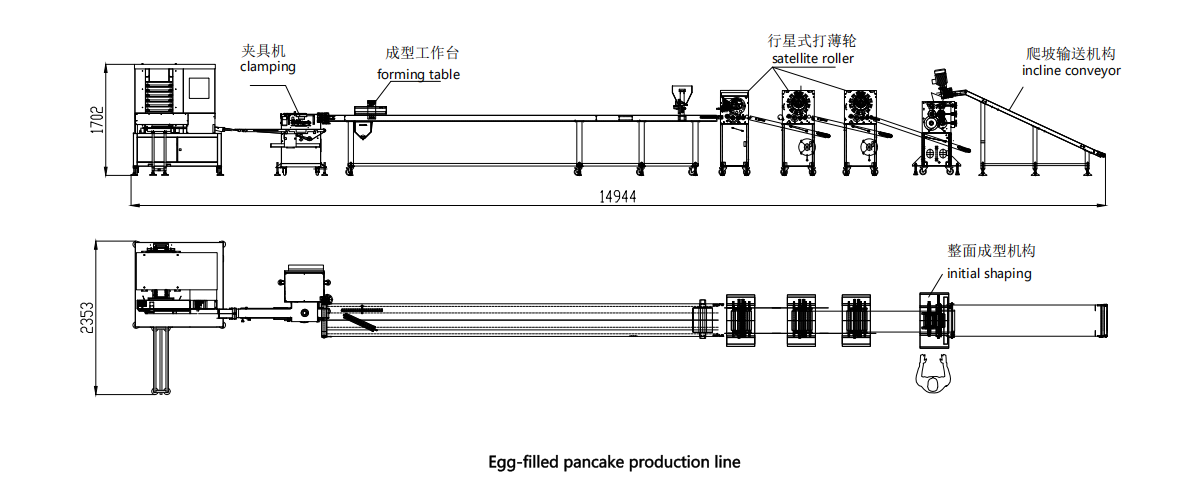

Mode | JH1801 |

| Dimension | 14944*2353*1702 (mm) |

| Capacity | 3000-4200pcs/h |

| Power specification | 380V, 50HZ, 3PH, 13KW |

| Material | SUS304, PE, Aluminum Allo |

| Finished product | SUS304, PE, Aluminum Alloy |

| Product size | Froze |

The Egg-filled Pancake Production Line is a fully automated system for mass-producing soft, egg-infused pancakes popular in East Asian street food and breakfast markets. This line combines batter mixing, griddling, egg depositing, and folding into a single process, delivering 600-800 pieces per hour with consistent egg-to-batter ratio. Key components include a 420 kg batter mixer, electric griddle (220V/380V), and automatic folding conveyor—all constructed with 304 stainless steel for food safety . It eliminates manual errors in egg distribution and cooking time, making it ideal for fast-food chains and breakfast catering services.

Batter Metering System: Accurate volume control (50-150 g per pancake) with viscosity sensors to prevent lumps .

Automatic Egg Injector: Deposits 10-20 ml of egg per pancake, with optional yolk/white separation for custom recipes .

Temperature-Controlled Griddle: 160-200°C adjustable range, with non-stick surface for easy release and minimal oil use .

Recipe Customization: Supports sweet (sugar, honey) and savory (scallion, cheese) variations by integrating ingredient feeders .

Compact Design: 3000×1200×1800 mm footprint, suitable for small to medium-sized food factories .

Fast-Food Chains: Breakfast menus and snack counters in urban areas (e.g., Chinese street food stalls, Korean convenience stores).

Cafeterias & Schools: Nutritious breakfast options with customizable egg content.

Frozen Food Production: Pre-cooked pancakes for microwaveable frozen meals.

Adaptable to Chinese "dan bing" (scallion egg pancakes) and Korean "gyeran bbang" (sweet egg bread) with mold adjustments .

Yes—the injector offers 10-20 ml egg per pancake, with digital controls for precise customization .

Griddles feature removable non-stick plates, and batter lines have CIP (Clean-in-Place) systems for 15-minute cleaning cycles .

Electric heating technology cuts energy use by 50% compared to gas-powered griddles, with rapid heat-up (5 minutes).

Mode | JH1801 |

| Dimension | 14944*2353*1702 (mm) |

| Capacity | 3000-4200pcs/h |

| Power specification | 380V, 50HZ, 3PH, 13KW |

| Material | SUS304, PE, Aluminum Allo |

| Finished product | SUS304, PE, Aluminum Alloy |

| Product size | Froze |

The Egg-filled Pancake Production Line is a fully automated system for mass-producing soft, egg-infused pancakes popular in East Asian street food and breakfast markets. This line combines batter mixing, griddling, egg depositing, and folding into a single process, delivering 600-800 pieces per hour with consistent egg-to-batter ratio. Key components include a 420 kg batter mixer, electric griddle (220V/380V), and automatic folding conveyor—all constructed with 304 stainless steel for food safety . It eliminates manual errors in egg distribution and cooking time, making it ideal for fast-food chains and breakfast catering services.

Batter Metering System: Accurate volume control (50-150 g per pancake) with viscosity sensors to prevent lumps .

Automatic Egg Injector: Deposits 10-20 ml of egg per pancake, with optional yolk/white separation for custom recipes .

Temperature-Controlled Griddle: 160-200°C adjustable range, with non-stick surface for easy release and minimal oil use .

Recipe Customization: Supports sweet (sugar, honey) and savory (scallion, cheese) variations by integrating ingredient feeders .

Compact Design: 3000×1200×1800 mm footprint, suitable for small to medium-sized food factories .

Fast-Food Chains: Breakfast menus and snack counters in urban areas (e.g., Chinese street food stalls, Korean convenience stores).

Cafeterias & Schools: Nutritious breakfast options with customizable egg content.

Frozen Food Production: Pre-cooked pancakes for microwaveable frozen meals.

Adaptable to Chinese "dan bing" (scallion egg pancakes) and Korean "gyeran bbang" (sweet egg bread) with mold adjustments .

Yes—the injector offers 10-20 ml egg per pancake, with digital controls for precise customization .

Griddles feature removable non-stick plates, and batter lines have CIP (Clean-in-Place) systems for 15-minute cleaning cycles .

Electric heating technology cuts energy use by 50% compared to gas-powered griddles, with rapid heat-up (5 minutes).