close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

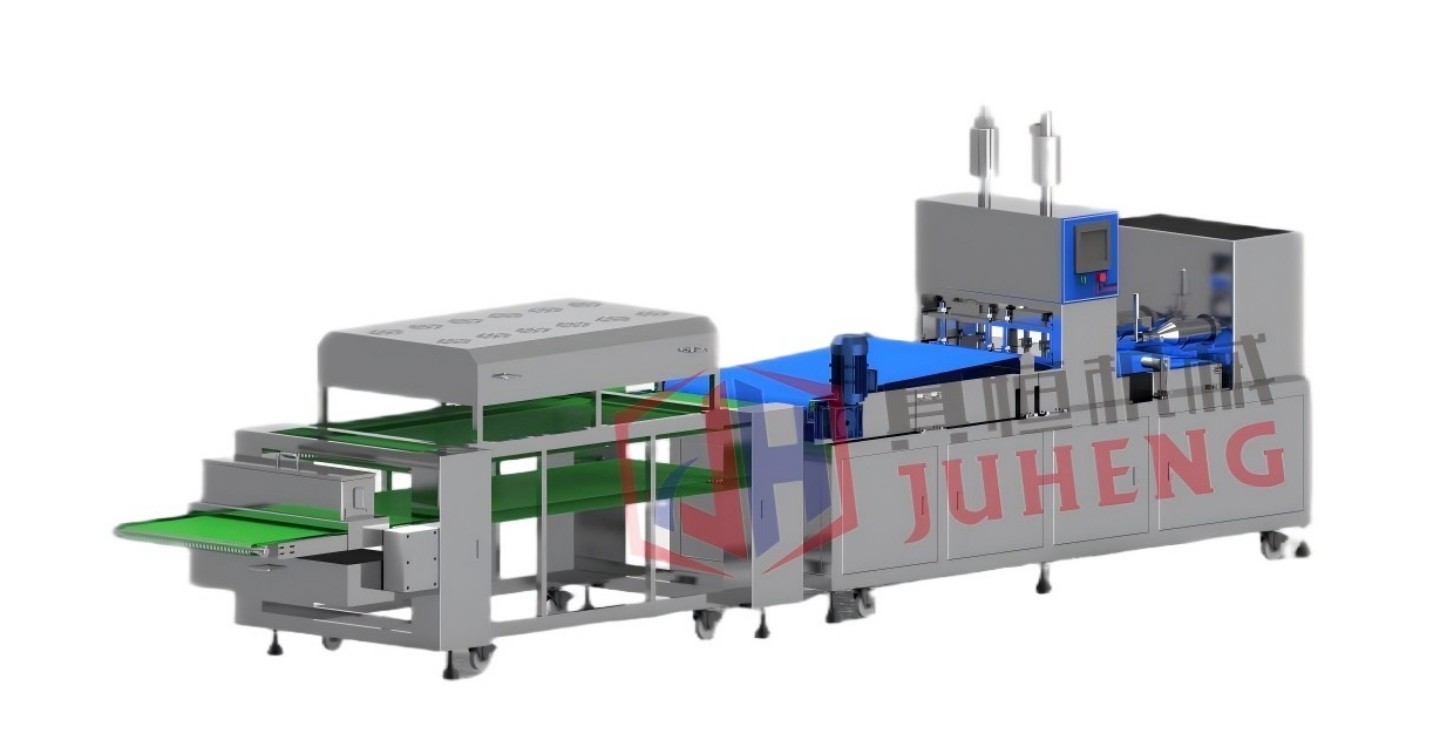

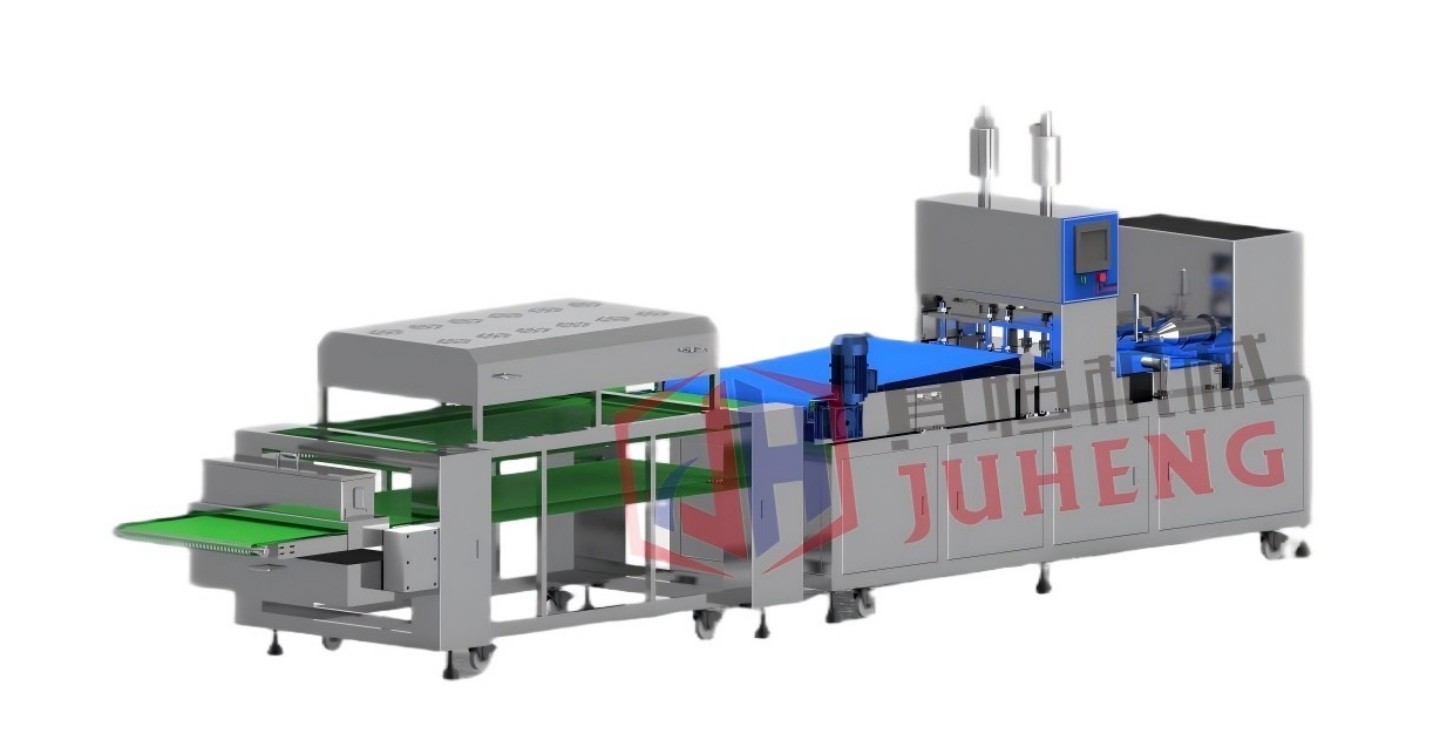

Mode | JH1902 |

| Dimension | 7478*1126*1579 (mm) |

Bread size | 25cm (for reference) |

Capacit | 1000-2000pcs/h |

Power specification | 380V, 50HZ, 3PH, 66KW |

| Finished product | Hot-pressing |

| Product size | Adjustable |

The Automatic SS Chinese Meat Pie Line is a highly efficient, integrated production system designed to streamline the manufacturing of delicious, consistent Chinese meat pies. This state-of-the-art line automates the entire process—from dough division and initial shaping to final forming—ensuring high output rates and uniform product quality. Beyond traditional Chinese meat pies, its versatility allows it to produce other popular items, such as Burek (a savory pastry) and cheese beef rolls, making it an ideal solution for food processing units looking to diversify their product offerings and scale up production with minimal manual intervention.

Built with food safety and efficiency in mind, the line uses high-quality materials and automated controls to eliminate human error and reduce labor costs. Its modular design allows for easy adjustments, ensuring it can adapt to different product recipes and sizes, while its high throughput makes it suitable for both large factories and growing businesses aiming to meet increasing market demand.

The line boasts a remarkable capacity of 3800-4200 pieces per hour (based on 100g per piece), significantly boosting production efficiency compared to manual or semi-automated systems. This high throughput ensures that large orders—whether for traditional Chinese meat pies, Burek, or cheese beef rolls—can be fulfilled swiftly, helping businesses meet tight deadlines and high market demands. The consistent output also reduces the risk of stockouts, supporting steady sales and customer satisfaction.

With fully automated processes—including dough dividing (for uniform portion sizes), initial shaping (to ensure consistent thickness), and consecutive sheeting (for smooth dough texture)—the line guarantees that every product maintains uniform weight, thickness, and appearance. This consistency is crucial for building brand reliability: whether a customer buys a meat pie or a cheese beef roll, they can expect the same high quality every time. The automated controls also reduce the risk of contamination, as manual handling of dough is minimized.

The line is engineered to handle a wide range of products, thanks to its easy adjustment and customization capabilities. Producers can switch between traditional Chinese meat pies, spiral-shaped Burek, and stuffed cheese beef rolls without needing multiple specialized machines. This flexibility allows businesses to cater to diverse market preferences (e.g., regional tastes or seasonal trends) and expand their product portfolios effortlessly. The adjustable product size feature further enhances this versatility, enabling production of different-sized items to target various customer segments (e.g., individual servings or family packs).

Constructed with SUS304 stainless steel (for food-contact parts) and PE (for non-food-contact components), the line meets strict food safety standards and is resistant to corrosion and wear. The durable materials ensure the line can withstand the rigors of daily industrial use, while the smooth surfaces and removable parts make cleaning and maintenance quick and easy. It operates on 380V, 50HZ, 3PH, 22KW power specifications, delivering stable performance during long production runs without excessive energy consumption.

Perfect for mass production of Chinese meat pies, Burek, and cheese beef rolls to meet market and customer demands. The line’s high capacity (3800-4200 pieces per hour) and consistent quality help factories scale output, reduce production costs, and supply products to retailers, supermarkets, and foodservice providers.

Provides standardized and consistent meat-based pastries for chain restaurants, fast-food outlets, and catering services. Whether used as a main dish, snack, or side item, the line ensures every product meets the same quality standards across all locations, maintaining brand consistency and satisfying customer expectations.

Offers an efficient and stable production line for food export enterprises. The line’s ability to produce diverse products (e.g., Burek for European markets or cheese beef rolls for Middle Eastern markets) and adhere to international food safety standards makes it suitable for meeting the demands of global customers, supporting businesses in expanding their export operations.

The line’s stated capacity of 3800-4200 pieces per hour is based on 100g per piece. Larger or heavier products (e.g., 150g meat pies) will reduce the hourly output, while smaller or lighter items (e.g., 80g cheese rolls) may increase it. We recommend sharing your specific product weight and size to get an accurate capacity estimate.

To tailor the line to your needs, please provide three key details: your target product size (weight, dimensions, and type, e.g., meat pie or Burek), your desired production capacity (e.g., number of pieces per hour), and your factory layout (available space for installation). This helps us adjust the line’s configuration for optimal performance.

The production cycle is approximately 2 months, though this may vary slightly depending on customizations (e.g., adding specialized shaping tools for Burek or adjusting the dough handling process for cheese rolls). We will confirm the timeline once your requirements are finalized.

The line comes with a 1-year warranty covering manufacturing defects and mechanical issues. During this period, our team will provide repair, replacement, or technical support for qualifying components.

Mode | JH1902 |

| Dimension | 7478*1126*1579 (mm) |

Bread size | 25cm (for reference) |

Capacit | 1000-2000pcs/h |

Power specification | 380V, 50HZ, 3PH, 66KW |

| Finished product | Hot-pressing |

| Product size | Adjustable |

The Automatic SS Chinese Meat Pie Line is a highly efficient, integrated production system designed to streamline the manufacturing of delicious, consistent Chinese meat pies. This state-of-the-art line automates the entire process—from dough division and initial shaping to final forming—ensuring high output rates and uniform product quality. Beyond traditional Chinese meat pies, its versatility allows it to produce other popular items, such as Burek (a savory pastry) and cheese beef rolls, making it an ideal solution for food processing units looking to diversify their product offerings and scale up production with minimal manual intervention.

Built with food safety and efficiency in mind, the line uses high-quality materials and automated controls to eliminate human error and reduce labor costs. Its modular design allows for easy adjustments, ensuring it can adapt to different product recipes and sizes, while its high throughput makes it suitable for both large factories and growing businesses aiming to meet increasing market demand.

The line boasts a remarkable capacity of 3800-4200 pieces per hour (based on 100g per piece), significantly boosting production efficiency compared to manual or semi-automated systems. This high throughput ensures that large orders—whether for traditional Chinese meat pies, Burek, or cheese beef rolls—can be fulfilled swiftly, helping businesses meet tight deadlines and high market demands. The consistent output also reduces the risk of stockouts, supporting steady sales and customer satisfaction.

With fully automated processes—including dough dividing (for uniform portion sizes), initial shaping (to ensure consistent thickness), and consecutive sheeting (for smooth dough texture)—the line guarantees that every product maintains uniform weight, thickness, and appearance. This consistency is crucial for building brand reliability: whether a customer buys a meat pie or a cheese beef roll, they can expect the same high quality every time. The automated controls also reduce the risk of contamination, as manual handling of dough is minimized.

The line is engineered to handle a wide range of products, thanks to its easy adjustment and customization capabilities. Producers can switch between traditional Chinese meat pies, spiral-shaped Burek, and stuffed cheese beef rolls without needing multiple specialized machines. This flexibility allows businesses to cater to diverse market preferences (e.g., regional tastes or seasonal trends) and expand their product portfolios effortlessly. The adjustable product size feature further enhances this versatility, enabling production of different-sized items to target various customer segments (e.g., individual servings or family packs).

Constructed with SUS304 stainless steel (for food-contact parts) and PE (for non-food-contact components), the line meets strict food safety standards and is resistant to corrosion and wear. The durable materials ensure the line can withstand the rigors of daily industrial use, while the smooth surfaces and removable parts make cleaning and maintenance quick and easy. It operates on 380V, 50HZ, 3PH, 22KW power specifications, delivering stable performance during long production runs without excessive energy consumption.

Perfect for mass production of Chinese meat pies, Burek, and cheese beef rolls to meet market and customer demands. The line’s high capacity (3800-4200 pieces per hour) and consistent quality help factories scale output, reduce production costs, and supply products to retailers, supermarkets, and foodservice providers.

Provides standardized and consistent meat-based pastries for chain restaurants, fast-food outlets, and catering services. Whether used as a main dish, snack, or side item, the line ensures every product meets the same quality standards across all locations, maintaining brand consistency and satisfying customer expectations.

Offers an efficient and stable production line for food export enterprises. The line’s ability to produce diverse products (e.g., Burek for European markets or cheese beef rolls for Middle Eastern markets) and adhere to international food safety standards makes it suitable for meeting the demands of global customers, supporting businesses in expanding their export operations.

The line’s stated capacity of 3800-4200 pieces per hour is based on 100g per piece. Larger or heavier products (e.g., 150g meat pies) will reduce the hourly output, while smaller or lighter items (e.g., 80g cheese rolls) may increase it. We recommend sharing your specific product weight and size to get an accurate capacity estimate.

To tailor the line to your needs, please provide three key details: your target product size (weight, dimensions, and type, e.g., meat pie or Burek), your desired production capacity (e.g., number of pieces per hour), and your factory layout (available space for installation). This helps us adjust the line’s configuration for optimal performance.

The production cycle is approximately 2 months, though this may vary slightly depending on customizations (e.g., adding specialized shaping tools for Burek or adjusting the dough handling process for cheese rolls). We will confirm the timeline once your requirements are finalized.

The line comes with a 1-year warranty covering manufacturing defects and mechanical issues. During this period, our team will provide repair, replacement, or technical support for qualifying components.