close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

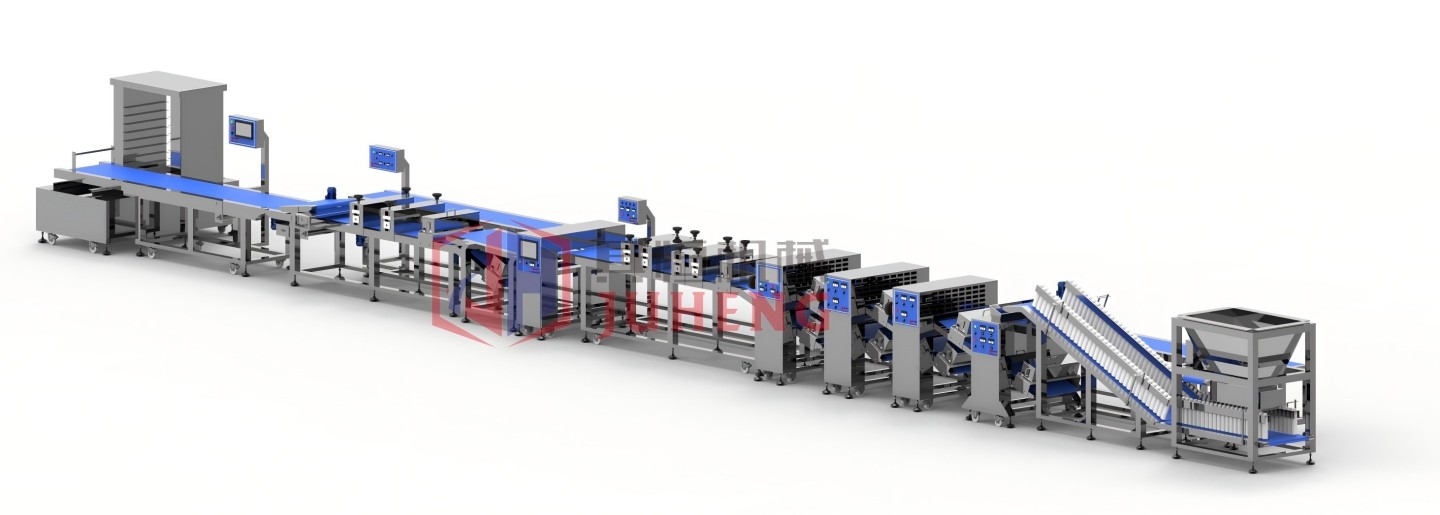

Mode | JH1902 |

| Dimension | 18141mm(L)*2605mm(W)*1675mm(H) |

Capacit | 3000-9000/h |

Power specification | 380V, 50HZ, 3PH, 29KW |

The Automatic SS Donut Bakery Line is a high-efficiency, versatile automated system designed to produce both ring-style (with a hole) and berliner (hole-less) donuts in a wide range of sizes. Engineered for commercial bakeries and food processing plants, this line balances high-volume output with flexible product design, enabling businesses to meet substantial order demands while adapting to market trends (e.g., mini donuts, filled berliners, or gluten-free varieties). At its core, the line uses precision-engineered forming rolls, cutting mechanisms, and conveying systems to guarantee uniformity in shape, size, and appearance—critical for maintaining brand standards and customer satisfaction. Constructed with SUS304 stainless steel (food-safe and corrosion-resistant), it prioritizes hygiene and durability, supporting continuous production runs with minimal downtime. Whether for retail, food service, or export, this line transforms raw dough into polished, ready-to-fry/bake donuts, reducing labor costs and human error while maximizing throughput.

Seamlessly switches between ring-style and berliner donuts without major mechanical adjustments, eliminating the need for separate equipment for different product types.

Easily adjustable settings for donut diameter (from 5cm to 12cm) and thickness, allowing quick transitions between standard, mini, or jumbo sizes to match customer preferences or seasonal promotions.

Compatible with various dough formulations, including wheat-based, gluten-free, and whole-grain options, catering to dietary restrictions and consumer demand for healthier alternatives.

Optimized for high-speed output, with a capacity range of 3000-9000pcs/h (adjustable based on donut size and complexity). This makes it ideal for operations handling large orders (e.g., supermarket chains, concession stands, or bulk export).

Streamlined conveying systems minimize dough handling time, ensuring a steady flow from forming to the next production stage (e.g., frying, glazing, or cooling), reducing bottlenecks and maximizing efficiency.

Precision forming rolls and cutting mechanisms ensure every donut has uniform shape, size, and weight—eliminating irregularities that lead to customer complaints or product waste.

SUS304 stainless steel construction resists rust and corrosion, while smooth surfaces and detachable components make cleaning fast and thorough, complying with global food safety standards (e.g., FDA, EU 10/2011).

Operates on a 380V, 50HZ, 3PH power supply with a total power of 29KW, delivering reliable performance for long production shifts without overheating or power fluctuations.

Ideal for large-scale bakeries supplying donuts to grocery stores, convenience stores, and coffee shops. The line’s high capacity ensures timely fulfillment of bulk orders, while its versatility supports a diverse product portfolio.

Supports plants specializing in frozen or packaged donuts for retail or food service. The line’s consistency ensures frozen donuts maintain their shape and texture after thawing, meeting the strict quality requirements of retail brands.

Designed to meet international standards for hygiene and product uniformity, making it suitable for donut export to global markets. Its ability to adapt to regional size preferences (e.g., smaller donuts for Asian markets, larger for North America) enhances market competitiveness.

Capacity is directly related to donut size and style. For example, mini ring donuts (5cm diameter) can reach up to 9000pcs/h, while large berliner donuts (12cm diameter) may yield around 3000pcs/h. Our team can provide a precise capacity estimate based on your specific product.

To tailor the line to your needs, please share:

Target donut size (diameter, thickness, and weight).

Desired production capacity (hourly or daily output goals).

Factory layout (available floor space, integration with existing equipment like fryers or glazers, and utility access).

Mode | JH1902 |

| Dimension | 18141mm(L)*2605mm(W)*1675mm(H) |

Capacit | 3000-9000/h |

Power specification | 380V, 50HZ, 3PH, 29KW |

The Automatic SS Donut Bakery Line is a high-efficiency, versatile automated system designed to produce both ring-style (with a hole) and berliner (hole-less) donuts in a wide range of sizes. Engineered for commercial bakeries and food processing plants, this line balances high-volume output with flexible product design, enabling businesses to meet substantial order demands while adapting to market trends (e.g., mini donuts, filled berliners, or gluten-free varieties). At its core, the line uses precision-engineered forming rolls, cutting mechanisms, and conveying systems to guarantee uniformity in shape, size, and appearance—critical for maintaining brand standards and customer satisfaction. Constructed with SUS304 stainless steel (food-safe and corrosion-resistant), it prioritizes hygiene and durability, supporting continuous production runs with minimal downtime. Whether for retail, food service, or export, this line transforms raw dough into polished, ready-to-fry/bake donuts, reducing labor costs and human error while maximizing throughput.

Seamlessly switches between ring-style and berliner donuts without major mechanical adjustments, eliminating the need for separate equipment for different product types.

Easily adjustable settings for donut diameter (from 5cm to 12cm) and thickness, allowing quick transitions between standard, mini, or jumbo sizes to match customer preferences or seasonal promotions.

Compatible with various dough formulations, including wheat-based, gluten-free, and whole-grain options, catering to dietary restrictions and consumer demand for healthier alternatives.

Optimized for high-speed output, with a capacity range of 3000-9000pcs/h (adjustable based on donut size and complexity). This makes it ideal for operations handling large orders (e.g., supermarket chains, concession stands, or bulk export).

Streamlined conveying systems minimize dough handling time, ensuring a steady flow from forming to the next production stage (e.g., frying, glazing, or cooling), reducing bottlenecks and maximizing efficiency.

Precision forming rolls and cutting mechanisms ensure every donut has uniform shape, size, and weight—eliminating irregularities that lead to customer complaints or product waste.

SUS304 stainless steel construction resists rust and corrosion, while smooth surfaces and detachable components make cleaning fast and thorough, complying with global food safety standards (e.g., FDA, EU 10/2011).

Operates on a 380V, 50HZ, 3PH power supply with a total power of 29KW, delivering reliable performance for long production shifts without overheating or power fluctuations.

Ideal for large-scale bakeries supplying donuts to grocery stores, convenience stores, and coffee shops. The line’s high capacity ensures timely fulfillment of bulk orders, while its versatility supports a diverse product portfolio.

Supports plants specializing in frozen or packaged donuts for retail or food service. The line’s consistency ensures frozen donuts maintain their shape and texture after thawing, meeting the strict quality requirements of retail brands.

Designed to meet international standards for hygiene and product uniformity, making it suitable for donut export to global markets. Its ability to adapt to regional size preferences (e.g., smaller donuts for Asian markets, larger for North America) enhances market competitiveness.

Capacity is directly related to donut size and style. For example, mini ring donuts (5cm diameter) can reach up to 9000pcs/h, while large berliner donuts (12cm diameter) may yield around 3000pcs/h. Our team can provide a precise capacity estimate based on your specific product.

To tailor the line to your needs, please share:

Target donut size (diameter, thickness, and weight).

Desired production capacity (hourly or daily output goals).

Factory layout (available floor space, integration with existing equipment like fryers or glazers, and utility access).