close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

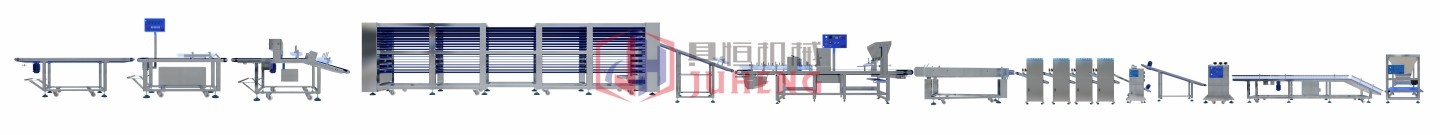

Mode | JH1801 |

| Dimension | 31118*1550*1648 (mm) |

| Capacity | 5500-8600pcs/h |

| Power specification | 380V, 50HZ, 3PH, 21KW |

| Material | SUS304, PE |

| Finished product | Unbaked, frozen |

| Product size | Adjustable |

The Custom Lachha Paratha Production Line is a high-performance, flexible system developed from years of expertise in traditional pastry manufacturing. Designed for medium-to-large-scale food businesses, this line specializes in producing frozen, uncooked Lachha Paratha dough discs—ideal for distribution to consumers who finish cooking at home via baking or pan-frying. Available in fully automated and semi-automated models, it balances efficiency, adaptability, and cost-effectiveness, making it suitable for growing enterprises without unnecessary complexity. At its core, the line uses precision shaping and layering technology to ensure each paratha retains its signature crisp-yet-tender texture after freezing, storage, and end-user preparation. Constructed with SUS304 stainless steel and PE (food-safe materials), it complies with global hygiene standards, while adjustable settings support regional taste preferences (e.g., spiced, herb-infused, or plain Lachha Parathas). Whether for retail frozen food sections, catering chains, or export, this line delivers consistent quality while reducing labor costs and scaling production to meet demand.

Precision-engineered shaping and layering mechanisms ensure uniform thickness and flakiness, even after freezing and end-user cooking (pan-frying or baking). This guarantees layers separate beautifully without becoming greasy—a key characteristic of authentic Lachha Parathas.

Automated processes eliminate human variability, ensuring every dough disc meets the same high standards for texture, appearance, and weight, reducing product waste and customer complaints.

Available in fully automated and semi-automated models, allowing businesses to choose a configuration that matches their budget, factory size, and labor resources.

Modular design supports easy upgrades (e.g., adding a dough divider or stacking module) as business grows, avoiding the need for full equipment replacement when scaling production.

Boasts a capacity range of 5500-8600pcs/h (adjustable based on paratha size) and operates on a 380V, 50HZ, 3PH power supply with a total power of 21KW, balancing high output with energy efficiency.

Adjustable settings for dough weight (50g to 200g per disc), size (10cm to 25cm diameter), and layering density, enabling customization to match regional preferences (e.g., thicker parathas for North Indian markets, thinner for Middle Eastern consumers).

Supports the addition of spices (e.g., cumin, coriander), herbs (e.g., mint, cilantro), or chopped vegetables (e.g., scallions, grated carrots) during dough preparation, allowing for a diverse product portfolio that caters to niche markets.

Ideal for mass production of frozen Lachha Paratha dough discs to supply retail stores, online grocery platforms, and food service providers. The line’s high capacity ensures efficient fulfillment of large orders, while its frozen output extends shelf life for broad distribution.

Provides standardized, ready-to-cook paratha dough for Indian restaurants, fast-food chains, and catering services. Uniform quality across all outlets ensures customers receive the same flaky paratha at every location, strengthening brand consistency.

Meets international standards for frozen food hygiene and quality, making it suitable for exporting to global markets (e.g., Europe, North America, or Southeast Asia). Its ability to adapt to regional tastes and size preferences enhances competitiveness in diverse markets.

Capacity ranges from 5500-8600pcs/h, with smaller parathas (e.g., 10cm diameter, 50g weight) yielding higher output and larger parathas (e.g., 25cm diameter, 200g weight) reducing throughput slightly. Our team can calculate exact capacity based on your product specifications.

To tailor the line to your business, please provide:

Target paratha size (diameter, weight, and thickness).

Desired production capacity (hourly or daily output goals).

Factory layout (available space, integration with existing freezing equipment, and utility access).

Any specialized requirements (e.g., spice addition, gluten-free dough handling).

The production cycle is approximately 2 months, shorter than many industry counterparts, though this may extend slightly for complex customizations (e.g., adding a vegetable mixing module).

We provide a 1-year warranty covering all core components, including shaping mechanisms, conveyors, and control systems. Warranty service includes free part replacement and technical support for issues from normal use.

Payment is accepted via T/T or L/C. The terms require 40% of the total amount as a deposit to start production, with the remaining balance due before delivery.

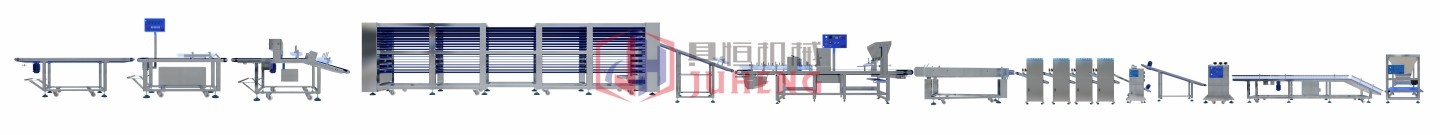

Mode | JH1801 |

| Dimension | 31118*1550*1648 (mm) |

| Capacity | 5500-8600pcs/h |

| Power specification | 380V, 50HZ, 3PH, 21KW |

| Material | SUS304, PE |

| Finished product | Unbaked, frozen |

| Product size | Adjustable |

The Custom Lachha Paratha Production Line is a high-performance, flexible system developed from years of expertise in traditional pastry manufacturing. Designed for medium-to-large-scale food businesses, this line specializes in producing frozen, uncooked Lachha Paratha dough discs—ideal for distribution to consumers who finish cooking at home via baking or pan-frying. Available in fully automated and semi-automated models, it balances efficiency, adaptability, and cost-effectiveness, making it suitable for growing enterprises without unnecessary complexity. At its core, the line uses precision shaping and layering technology to ensure each paratha retains its signature crisp-yet-tender texture after freezing, storage, and end-user preparation. Constructed with SUS304 stainless steel and PE (food-safe materials), it complies with global hygiene standards, while adjustable settings support regional taste preferences (e.g., spiced, herb-infused, or plain Lachha Parathas). Whether for retail frozen food sections, catering chains, or export, this line delivers consistent quality while reducing labor costs and scaling production to meet demand.

Precision-engineered shaping and layering mechanisms ensure uniform thickness and flakiness, even after freezing and end-user cooking (pan-frying or baking). This guarantees layers separate beautifully without becoming greasy—a key characteristic of authentic Lachha Parathas.

Automated processes eliminate human variability, ensuring every dough disc meets the same high standards for texture, appearance, and weight, reducing product waste and customer complaints.

Available in fully automated and semi-automated models, allowing businesses to choose a configuration that matches their budget, factory size, and labor resources.

Modular design supports easy upgrades (e.g., adding a dough divider or stacking module) as business grows, avoiding the need for full equipment replacement when scaling production.

Boasts a capacity range of 5500-8600pcs/h (adjustable based on paratha size) and operates on a 380V, 50HZ, 3PH power supply with a total power of 21KW, balancing high output with energy efficiency.

Adjustable settings for dough weight (50g to 200g per disc), size (10cm to 25cm diameter), and layering density, enabling customization to match regional preferences (e.g., thicker parathas for North Indian markets, thinner for Middle Eastern consumers).

Supports the addition of spices (e.g., cumin, coriander), herbs (e.g., mint, cilantro), or chopped vegetables (e.g., scallions, grated carrots) during dough preparation, allowing for a diverse product portfolio that caters to niche markets.

Ideal for mass production of frozen Lachha Paratha dough discs to supply retail stores, online grocery platforms, and food service providers. The line’s high capacity ensures efficient fulfillment of large orders, while its frozen output extends shelf life for broad distribution.

Provides standardized, ready-to-cook paratha dough for Indian restaurants, fast-food chains, and catering services. Uniform quality across all outlets ensures customers receive the same flaky paratha at every location, strengthening brand consistency.

Meets international standards for frozen food hygiene and quality, making it suitable for exporting to global markets (e.g., Europe, North America, or Southeast Asia). Its ability to adapt to regional tastes and size preferences enhances competitiveness in diverse markets.

Capacity ranges from 5500-8600pcs/h, with smaller parathas (e.g., 10cm diameter, 50g weight) yielding higher output and larger parathas (e.g., 25cm diameter, 200g weight) reducing throughput slightly. Our team can calculate exact capacity based on your product specifications.

To tailor the line to your business, please provide:

Target paratha size (diameter, weight, and thickness).

Desired production capacity (hourly or daily output goals).

Factory layout (available space, integration with existing freezing equipment, and utility access).

Any specialized requirements (e.g., spice addition, gluten-free dough handling).

The production cycle is approximately 2 months, shorter than many industry counterparts, though this may extend slightly for complex customizations (e.g., adding a vegetable mixing module).

We provide a 1-year warranty covering all core components, including shaping mechanisms, conveyors, and control systems. Warranty service includes free part replacement and technical support for issues from normal use.

Payment is accepted via T/T or L/C. The terms require 40% of the total amount as a deposit to start production, with the remaining balance due before delivery.