close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

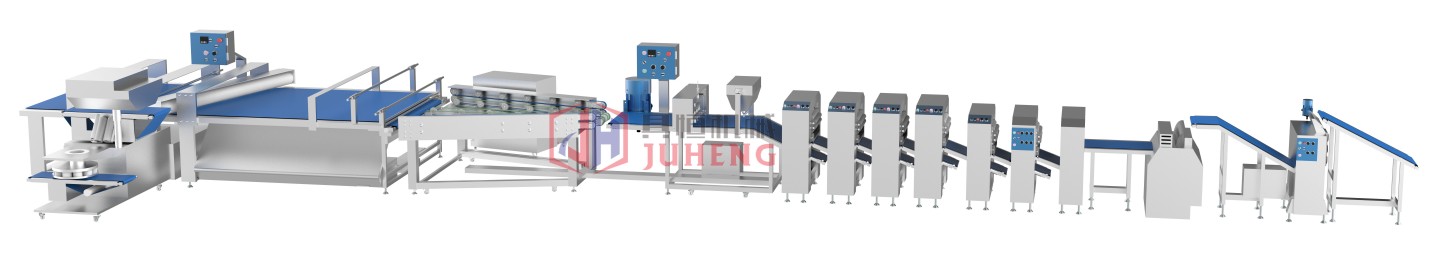

Mode | JH1801 |

| Dimension | 25307*1584*1843 (mm) |

| Capacity | 3800-4200pcs/h |

| Power specification | 380V, 50HZ, 3PH, 22KW |

| Material | SUS304, PE |

| Finished product | Unbaked, frozen |

| Product size | Adjustable |

The Chinese Hamburger Roujiamo Production Line is a specialized, industrial-grade system designed to produce high-quality frozen, unbaked Roujiamo dough rounds. Tailored for large-scale food factories and food service enterprises, this line prioritizes efficiency, freshness, and consistency—addressing the unique needs of Roujiamo production, where flaky layers and texture retention are critical. Unlike generic flatbread lines, it uses advanced lamination technology to create uniform, multi-layered dough shells that maintain their texture and flavor after thawing and baking. Constructed with SUS304 stainless steel (corrosion-resistant and food-safe) and premium imported electrical parts (from Taiwan, Japan, and Germany), the line delivers long-term reliability with minimal downtime. Its fixed configuration ensures stable output, while rapid freezing capabilities lock in freshness, extending shelf life without compromising the traditional taste of Roujiamo. Whether supplying to chain restaurants, retail frozen food sections, or export markets, this line transforms raw dough into standardized, ready-to-bake shells, reducing labor costs and ensuring brand consistency.

Designed exclusively for large-scale food factories, with a steady capacity range of 3800-4200pcs/h (adjustable based on dough round size). This ensures efficient fulfillment of high-volume orders, even during peak demand periods.

Fixed configuration minimizes mechanical downtime, with durable components that withstand continuous production runs—critical for industrial operations where interruptions impact profitability.

Operates on a 380V, 50HZ, 3PH power supply with a total power of 22KW, delivering consistent performance without power fluctuations or overheating.

Full SUS304 stainless steel body resists corrosion and rust, complying with strict food hygiene standards (e.g., China GB 4806.9, EU 10/2011) and simplifying cleaning and maintenance.

Premium imported electrical parts (from Taiwan, Japan, and Germany) ensure precision control and durability, reducing the risk of component failure and extending equipment lifespan.

Sleek, polished design reflects high craftsmanship, with smooth surfaces that prevent dough sticking and minimize waste.

Advanced lamination technology creates consistent flaky layers in every Roujiamo shell, with adjustable thickness control (0.5mm to 2mm) to meet specific product requirements (e.g., thick crusts for savory fillings, thin for delicate flavors).

Rapid freezing system locks in freshness immediately after forming, preserving the dough’s moisture and texture. Thawed shells retain their flakiness and shape during baking, ensuring the same quality as freshly made dough.

Produces uniform dough rounds with consistent weight (80g to 150g) and size (10cm to 15cm diameter), eliminating variations that affect filling capacity and customer experience.

Ideal for mass production of frozen Roujiamo dough shells to supply chain restaurants, catering services, and retail stores. The line’s high capacity and stability ensure factories can meet large-volume orders efficiently, while frozen output supports nationwide or regional distribution.

Provides standardized dough shells for Roujiamo chains, ensuring every outlet serves products with the same flaky texture and size. This consistency strengthens brand identity and customer loyalty, as consumers know what to expect from every location.

Meets international standards for frozen food hygiene and quality, making it suitable for exporting to global markets (e.g., North America, Europe, or Southeast Asia’s Chinese communities). Its ability to preserve traditional Roujiamo flavor in frozen form enhances appeal for international consumers.

Capacity ranges from 3800-4200pcs/h, with smaller dough rounds (e.g., 10cm diameter, 80g weight) yielding higher output and larger rounds (e.g., 15cm diameter, 150g weight) reducing throughput slightly. Our team can provide a precise capacity estimate based on your product specs.

To tailor the line to your needs, please share:

Target dough round size (diameter, weight, and thickness).

Desired production capacity (hourly or daily output goals).

Factory layout (available space, integration with existing freezing equipment, and utility access).

Any specialized requirements (e.g., gluten-free dough handling, specific layer count).

The production cycle is approximately 2 months, shorter than many industrial-grade lines, though this may extend for customizations (e.g., adding a dough cooling module or specialized lamination components).

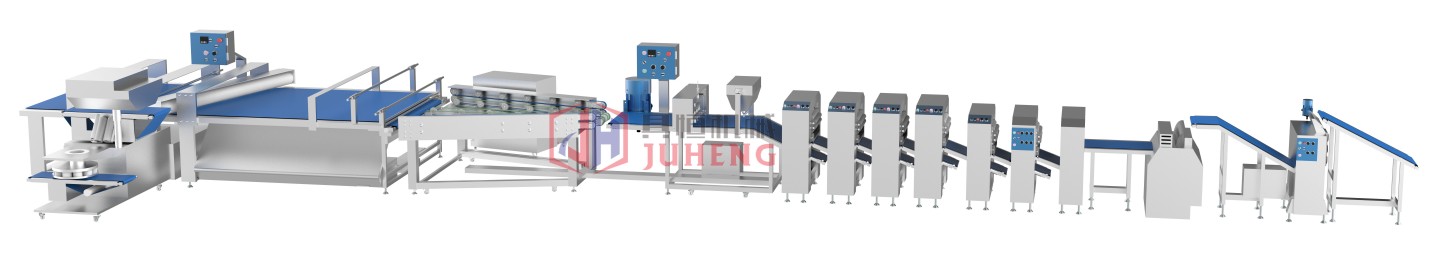

Mode | JH1801 |

| Dimension | 25307*1584*1843 (mm) |

| Capacity | 3800-4200pcs/h |

| Power specification | 380V, 50HZ, 3PH, 22KW |

| Material | SUS304, PE |

| Finished product | Unbaked, frozen |

| Product size | Adjustable |

The Chinese Hamburger Roujiamo Production Line is a specialized, industrial-grade system designed to produce high-quality frozen, unbaked Roujiamo dough rounds. Tailored for large-scale food factories and food service enterprises, this line prioritizes efficiency, freshness, and consistency—addressing the unique needs of Roujiamo production, where flaky layers and texture retention are critical. Unlike generic flatbread lines, it uses advanced lamination technology to create uniform, multi-layered dough shells that maintain their texture and flavor after thawing and baking. Constructed with SUS304 stainless steel (corrosion-resistant and food-safe) and premium imported electrical parts (from Taiwan, Japan, and Germany), the line delivers long-term reliability with minimal downtime. Its fixed configuration ensures stable output, while rapid freezing capabilities lock in freshness, extending shelf life without compromising the traditional taste of Roujiamo. Whether supplying to chain restaurants, retail frozen food sections, or export markets, this line transforms raw dough into standardized, ready-to-bake shells, reducing labor costs and ensuring brand consistency.

Designed exclusively for large-scale food factories, with a steady capacity range of 3800-4200pcs/h (adjustable based on dough round size). This ensures efficient fulfillment of high-volume orders, even during peak demand periods.

Fixed configuration minimizes mechanical downtime, with durable components that withstand continuous production runs—critical for industrial operations where interruptions impact profitability.

Operates on a 380V, 50HZ, 3PH power supply with a total power of 22KW, delivering consistent performance without power fluctuations or overheating.

Full SUS304 stainless steel body resists corrosion and rust, complying with strict food hygiene standards (e.g., China GB 4806.9, EU 10/2011) and simplifying cleaning and maintenance.

Premium imported electrical parts (from Taiwan, Japan, and Germany) ensure precision control and durability, reducing the risk of component failure and extending equipment lifespan.

Sleek, polished design reflects high craftsmanship, with smooth surfaces that prevent dough sticking and minimize waste.

Advanced lamination technology creates consistent flaky layers in every Roujiamo shell, with adjustable thickness control (0.5mm to 2mm) to meet specific product requirements (e.g., thick crusts for savory fillings, thin for delicate flavors).

Rapid freezing system locks in freshness immediately after forming, preserving the dough’s moisture and texture. Thawed shells retain their flakiness and shape during baking, ensuring the same quality as freshly made dough.

Produces uniform dough rounds with consistent weight (80g to 150g) and size (10cm to 15cm diameter), eliminating variations that affect filling capacity and customer experience.

Ideal for mass production of frozen Roujiamo dough shells to supply chain restaurants, catering services, and retail stores. The line’s high capacity and stability ensure factories can meet large-volume orders efficiently, while frozen output supports nationwide or regional distribution.

Provides standardized dough shells for Roujiamo chains, ensuring every outlet serves products with the same flaky texture and size. This consistency strengthens brand identity and customer loyalty, as consumers know what to expect from every location.

Meets international standards for frozen food hygiene and quality, making it suitable for exporting to global markets (e.g., North America, Europe, or Southeast Asia’s Chinese communities). Its ability to preserve traditional Roujiamo flavor in frozen form enhances appeal for international consumers.

Capacity ranges from 3800-4200pcs/h, with smaller dough rounds (e.g., 10cm diameter, 80g weight) yielding higher output and larger rounds (e.g., 15cm diameter, 150g weight) reducing throughput slightly. Our team can provide a precise capacity estimate based on your product specs.

To tailor the line to your needs, please share:

Target dough round size (diameter, weight, and thickness).

Desired production capacity (hourly or daily output goals).

Factory layout (available space, integration with existing freezing equipment, and utility access).

Any specialized requirements (e.g., gluten-free dough handling, specific layer count).

The production cycle is approximately 2 months, shorter than many industrial-grade lines, though this may extend for customizations (e.g., adding a dough cooling module or specialized lamination components).