close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

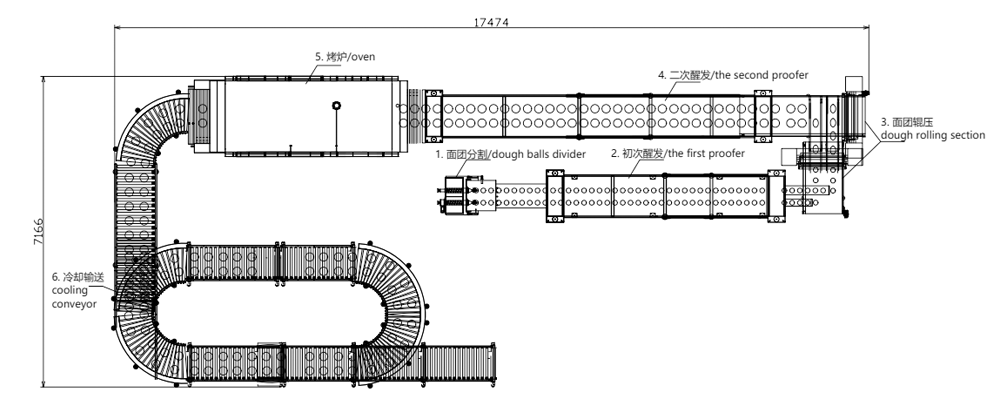

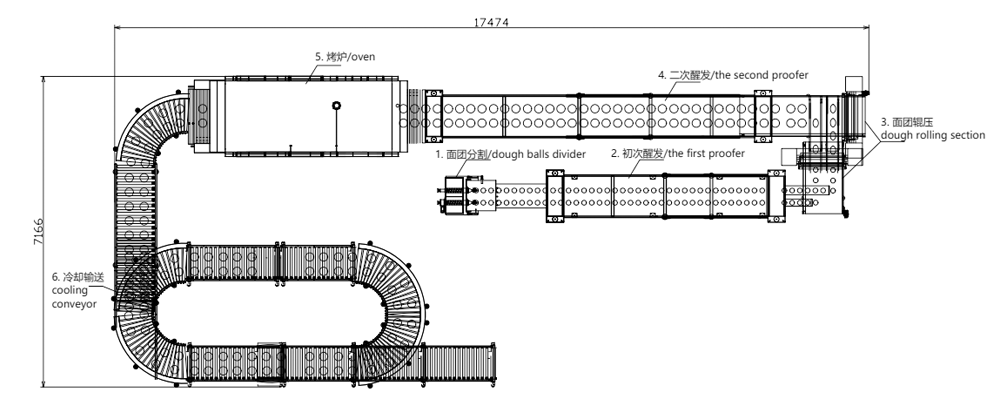

Mode | JH1801 |

| Dimension | 17474*7166*2430 (mm) |

| Capacity | Adjustable |

| Power specification | 380V, 50HZ, 3PH, 17.25KW |

| Material | SUS304, PE, Aluminum Allo |

| Finished product | Baked |

| Product size | Adjustable |

The Custom SS Pita Bread Line is a state-of-the-art, fully automated system designed to deliver high-efficiency, consistent, and scalable manufacturing of fresh, high-quality pita bread. Engineered for bakeries, food processing facilities, and catering operations of all sizes, this line integrates precision processes—from dough mixing and fermentation to baking and cooling—to meet the demands of both small-scale and industrial production. Whether producing traditional pita bread or customized variations (e.g., whole-grain or flavored options), the line ensures optimal texture and flavor while minimizing labor costs and operational complexity.

What sets this line apart is its adaptability: it can be customized to fit specific production needs, from adjusting product sizes to integrating with existing bakery equipment. The use of food-grade materials and automated controls ensures compliance with food safety standards and reduces the risk of human error, making it a reliable choice for businesses prioritizing quality and efficiency.

The line is configured to produce pita bread in a range of common diameters, and its molding station can be easily adjusted to achieve different product sizes. This flexibility allows businesses to meet standard market requirements (e.g., 6-inch or 8-inch pita) or cater to custom orders (e.g., larger pita for wraps). The adjustable product size feature eliminates the need for multiple specialized machines, saving both space and investment.

Operation is managed through a simple PLC (Programmable Logic Controller) touchscreen interface. This system allows for straightforward control of line speed and key parameters (e.g., baking temperature and fermentation time), significantly reducing the learning curve for staff. Even operators with limited experience can quickly master the system, minimizing training time and ensuring consistent operation across shifts.

Constructed with a solid frame and food-contact parts made from SUS304 stainless steel—a material known for its corrosion resistance and food safety compliance—the line is built for steady daily operation. The design prioritizes ease of access for routine cleaning and maintenance: removable components and smooth surfaces prevent dough buildup, reducing downtime and extending the equipment’s lifespan. Additionally, non-food-contact parts use durable materials like PE and aluminum alloy, ensuring long-term reliability.

The line follows a streamlined 6-step process to maximize efficiency: 1) dough balls divider (for uniform dough portions), 2) first proofer, to activate yeast, 3) dough rolling section (for consistent thickness), 4) second proofer, to enhance texture, 5) oven (for even baking), and 6) cooling conveyor (to preserve freshness). This sequential flow ensures each pita bread undergoes the same precise treatment, resulting in consistent quality batch after batch. It operates on 380V, 50HZ, 3PH, 17.25KW power specifications, balancing performance with energy efficiency.

Ideal for mass production of pita bread to meet large-market demands. The line’s high efficiency and adjustable capacity allow factories to scale output based on seasonal trends (e.g., increased demand during holidays) and maintain consistent quality for retailers and distributors.

Provides standardized and consistent pita bread for chain restaurants, fast-food outlets, and sandwich shops. Whether used for gyros, wraps, or standalone flatbreads, the line ensures every pita has the same texture and size across all locations, reinforcing brand identity and customer loyalty.

Offers an efficient and stable production line for food export enterprises. The line’s ability to adhere to international food safety standards (thanks to SUS304 stainless steel construction) and produce large volumes makes it suitable for meeting the strict requirements of global markets, supporting businesses in expanding their export reach.

The capacity is directly related to the size of your pita bread. Smaller pita (e.g., 6-inch) will yield a higher hourly output, while larger pita (e.g., 10-inch) may reduce output. Since the line’s capacity is adjustable, we recommend sharing your target product size to receive a customized capacity estimate tailored to your needs.

To customize the line for your operations, please provide three key details: your desired pita bread size (diameter and thickness), your target production capacity (e.g., number of pita per hour), and your factory layout (available space for installation). This helps us optimize the line’s configuration and ensure it integrates seamlessly with your existing processes.

The production cycle is approximately 2 months, though this may vary based on specific customizations (e.g., adjustments to the oven or cooling conveyor). We will provide a detailed timeline once your solution is finalized.

The line comes with a 1-year warranty covering manufacturing defects and mechanical failures. Our team will provide prompt repair or replacement services for qualifying issues, minimizing downtime for your operations.

Payment can be made via T/T (Telegraphic Transfer) or L/C (Letter of Credit). The terms require 40% of the total amount as a deposit to start production, with the remaining balance due before delivery of the line.

Mode | JH1801 |

| Dimension | 17474*7166*2430 (mm) |

| Capacity | Adjustable |

| Power specification | 380V, 50HZ, 3PH, 17.25KW |

| Material | SUS304, PE, Aluminum Allo |

| Finished product | Baked |

| Product size | Adjustable |

The Custom SS Pita Bread Line is a state-of-the-art, fully automated system designed to deliver high-efficiency, consistent, and scalable manufacturing of fresh, high-quality pita bread. Engineered for bakeries, food processing facilities, and catering operations of all sizes, this line integrates precision processes—from dough mixing and fermentation to baking and cooling—to meet the demands of both small-scale and industrial production. Whether producing traditional pita bread or customized variations (e.g., whole-grain or flavored options), the line ensures optimal texture and flavor while minimizing labor costs and operational complexity.

What sets this line apart is its adaptability: it can be customized to fit specific production needs, from adjusting product sizes to integrating with existing bakery equipment. The use of food-grade materials and automated controls ensures compliance with food safety standards and reduces the risk of human error, making it a reliable choice for businesses prioritizing quality and efficiency.

The line is configured to produce pita bread in a range of common diameters, and its molding station can be easily adjusted to achieve different product sizes. This flexibility allows businesses to meet standard market requirements (e.g., 6-inch or 8-inch pita) or cater to custom orders (e.g., larger pita for wraps). The adjustable product size feature eliminates the need for multiple specialized machines, saving both space and investment.

Operation is managed through a simple PLC (Programmable Logic Controller) touchscreen interface. This system allows for straightforward control of line speed and key parameters (e.g., baking temperature and fermentation time), significantly reducing the learning curve for staff. Even operators with limited experience can quickly master the system, minimizing training time and ensuring consistent operation across shifts.

Constructed with a solid frame and food-contact parts made from SUS304 stainless steel—a material known for its corrosion resistance and food safety compliance—the line is built for steady daily operation. The design prioritizes ease of access for routine cleaning and maintenance: removable components and smooth surfaces prevent dough buildup, reducing downtime and extending the equipment’s lifespan. Additionally, non-food-contact parts use durable materials like PE and aluminum alloy, ensuring long-term reliability.

The line follows a streamlined 6-step process to maximize efficiency: 1) dough balls divider (for uniform dough portions), 2) first proofer, to activate yeast, 3) dough rolling section (for consistent thickness), 4) second proofer, to enhance texture, 5) oven (for even baking), and 6) cooling conveyor (to preserve freshness). This sequential flow ensures each pita bread undergoes the same precise treatment, resulting in consistent quality batch after batch. It operates on 380V, 50HZ, 3PH, 17.25KW power specifications, balancing performance with energy efficiency.

Ideal for mass production of pita bread to meet large-market demands. The line’s high efficiency and adjustable capacity allow factories to scale output based on seasonal trends (e.g., increased demand during holidays) and maintain consistent quality for retailers and distributors.

Provides standardized and consistent pita bread for chain restaurants, fast-food outlets, and sandwich shops. Whether used for gyros, wraps, or standalone flatbreads, the line ensures every pita has the same texture and size across all locations, reinforcing brand identity and customer loyalty.

Offers an efficient and stable production line for food export enterprises. The line’s ability to adhere to international food safety standards (thanks to SUS304 stainless steel construction) and produce large volumes makes it suitable for meeting the strict requirements of global markets, supporting businesses in expanding their export reach.

The capacity is directly related to the size of your pita bread. Smaller pita (e.g., 6-inch) will yield a higher hourly output, while larger pita (e.g., 10-inch) may reduce output. Since the line’s capacity is adjustable, we recommend sharing your target product size to receive a customized capacity estimate tailored to your needs.

To customize the line for your operations, please provide three key details: your desired pita bread size (diameter and thickness), your target production capacity (e.g., number of pita per hour), and your factory layout (available space for installation). This helps us optimize the line’s configuration and ensure it integrates seamlessly with your existing processes.

The production cycle is approximately 2 months, though this may vary based on specific customizations (e.g., adjustments to the oven or cooling conveyor). We will provide a detailed timeline once your solution is finalized.

The line comes with a 1-year warranty covering manufacturing defects and mechanical failures. Our team will provide prompt repair or replacement services for qualifying issues, minimizing downtime for your operations.

Payment can be made via T/T (Telegraphic Transfer) or L/C (Letter of Credit). The terms require 40% of the total amount as a deposit to start production, with the remaining balance due before delivery of the line.